Project Details:

Location: San Antonio, Texas

Project Value: $119 Million

General Contractor: Alterman Management Group Inc.

Owner: SwRI (Southwest Research Institute)

Location: San Antonio, Texas

Project Value: $119 Million

General Contractor: Alterman Management Group Inc.

Owner: SwRI (Southwest Research Institute)

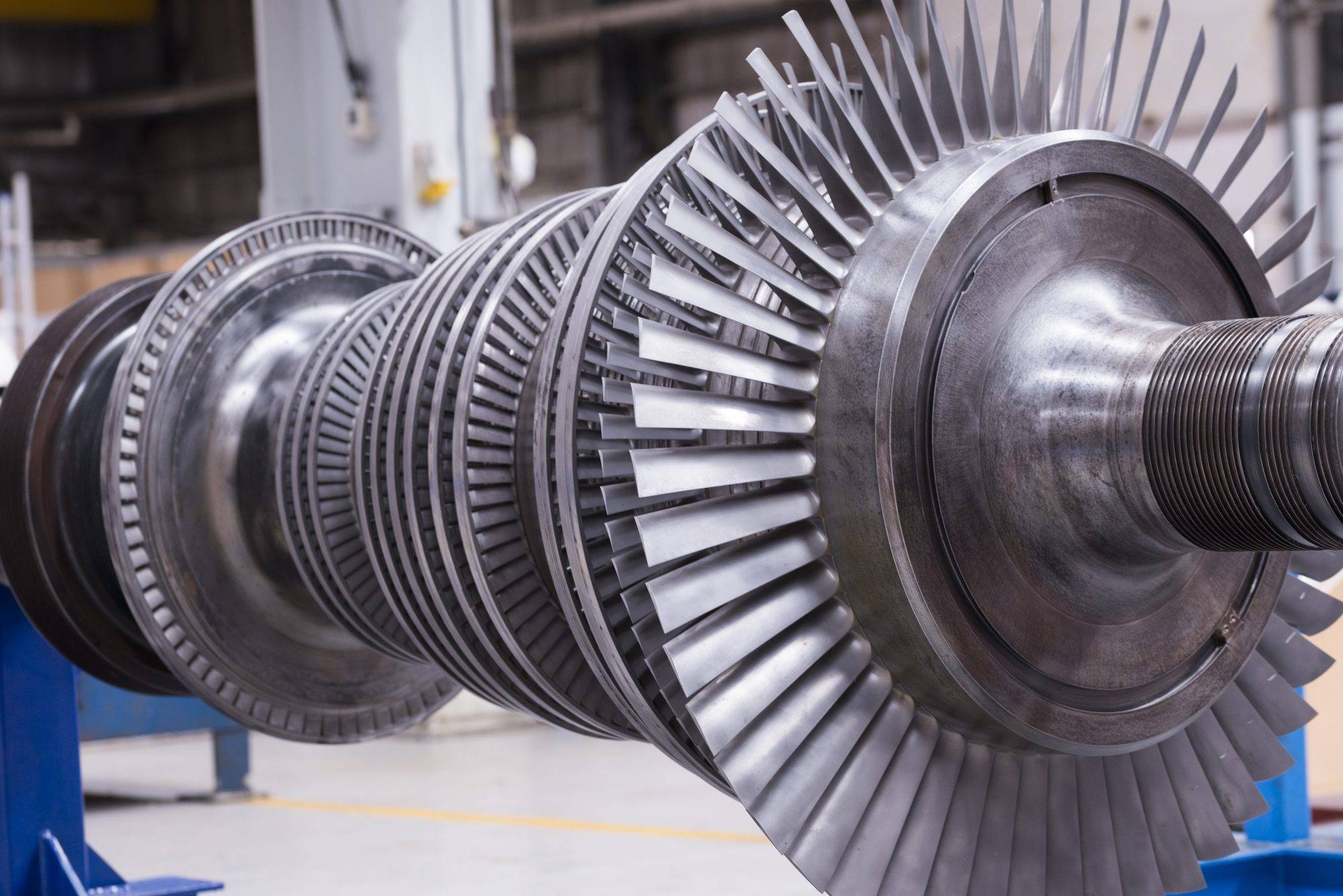

Our expert team took on the role of senior scheduler and project controls for an innovative $119 million supercritical carbon dioxide (sCO2) facility. This facility spans approximately 10 megawatts, and it represents a significant step forward in supercritical energy technology. Notably, the project’s primary goal is to advance supercritical CO₂ power cycles, which hold great promise for the future.

Initially, we developed a comprehensive project schedule that streamlined the various phases of construction. This schedule became the foundation for effective coordination among teams. In addition, we conducted regular updates to ensure all stakeholders remained informed and aligned. Our sCO₂ facility employs unique supercritical technology that enables the fluid to behave like a gas while maintaining the density of a liquid. As a result, this method allows for unprecedented efficiency in energy conversion and demonstrates the value of supercritical systems.

Moreover, this supercritical facility aims to increase energy efficiency significantly. Consequently, it will lead to reduced CO₂ emissions. With a lower environmental footprint, our project addresses pressing global concerns. We also recognize the importance of minimizing water usage. Therefore, the facility’s design incorporates advanced solutions that conserve this precious resource, another supercritical advantage.

Furthermore, the sCO2 technology we use is nontoxic and nonflammable, ensuring safety throughout the operations. Importantly, minor adjustments in temperature or pressure can lead to significant changes in the fluid’s density. This characteristic allows for efficient energy cycles and enhances overall supercritical power generation.

In conclusion, our diligent efforts as senior scheduler and project controls play a vital role in the successful implementation of this groundbreaking supercritical facility. We are proud to contribute to advancements that promise cleaner energy solutions for the supercritical future.

Precision’s project controls experts continuously advance the planning and scheduling processes for our clients. By leveraging in-depth knowledge of industry best practices and the latest methodologies, our team works closely with clients to refine their project timelines and ensure they align with their strategic objectives. Through fostering transparent communication and actively addressing the distinct challenges of each project, we strive to deliver tailored solutions that enhance efficiency and achieve success. Our dedication to excellence and teamwork guarantees that our clients receive top-tier service. Thus, enabling them to confidently navigate complex projects involving new supercritical technologies.

Project controls, planning, and scheduling are essential elements for the successful completion of projects. Furthermore, effective project controls allow for continuous monitoring and management of all project aspects throughout its duration. Helping teams identify potential risks and implement timely interventions. Planning provides a clear framework for the project, detailing tasks, timelines, and resource allocation. Moreover, this helps streamline operations and enhance stakeholder communication. Thus, scheduling is a vital instrument for tracking project progress and ensuring milestones are achieved, ultimately minimizing delays and managing costs. Collectively, these components contribute to greater efficiency, enhanced collaboration, and informed decision-making, resulting in superior quality outcomes and heightened client satisfaction.